How to Select Materials for Working in a Chemical Environment?

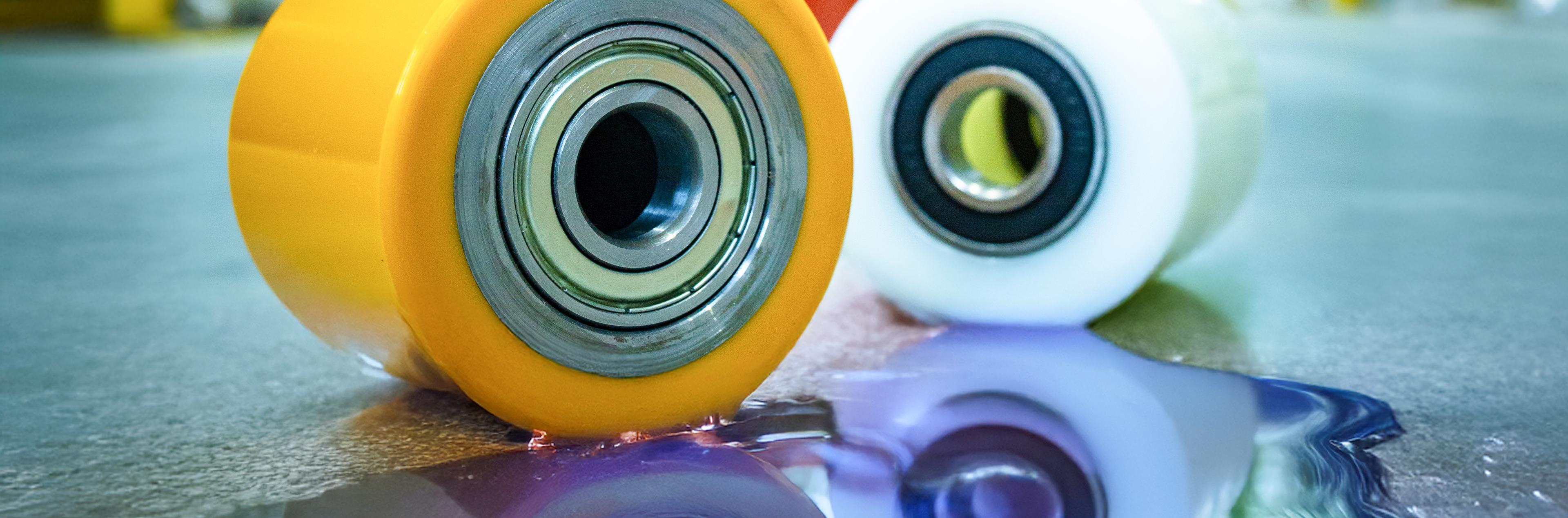

Choosing wheels and caster assemblies for environments where they come into contact with chemicals is crucial for ensuring long-term and trouble-free operation. Chemical resistance depends on the type and concentration of the substance, as well as the duration of material exposure to it.

Chemical Resistance Table

In our table, you will find approximate information about the chemical resistance of various materials used in wheel production. Compare which materials best suit your needs and choose those that will provide optimal performance in your working environment.

| Type of Substance | Rubber | Polyurethane | Polypropylene | Polyamide | Thermo-resistant Plastic | Vulkollan | Thermoplastic Elastomer |

|---|---|---|---|---|---|---|---|

| Ethanol | + | + | No | + | + | No | + |

| Gasoline | No | + | No | + | + | No | No |

| Benzene | - | + | - | + | + | No | No |

| Trichloroethylene | - | + | - | No | + | - | - |

| Toluene and Xylene | - | + | + | + | No | No | No |

| Crude Oil | No | + | No | + | + | + | No |

| Mineral Oils | No | + | No | + | + | + | No |

| Acetone | - | No | No | + | + | - | + |

| Nitric Acid 25-50% | - | - | + | No | No | - | + |

| Chromium Trioxide 10% | - | - | + | No | + | - | + |

| Chlorine Water | + | - | + | No | + | - | + |

| Acetic Acid | - | - | + | + | + | - | + |

| Hydrochloric Acid | No | - | + | No | + | - | + |

| Sulfuric Acid 25% | - | - | + | No | + | - | + |

| Hydroxides | + | - | + | + | No | - | + |

Legend

+ Resistance

O Partial Resistance

- No Resistance

If you have any questions regarding the selection of appropriate materials for specific chemical conditions, please contact our experts. We are here to help you choose the most suitable solutions for your needs.